Industries We Serve

Precision-crafted components, built for every process where performance matters

At Arvico Rubber, we specialize in developing high-performance rubber components that power critical applications across diverse industrial sectors. With decades of expertise, we deliver both standard and custom-engineered solutions that meet exacting specifications, performance standards, and regulatory requirements. Our in-house team of application engineers collaborates closely with clients to design and manufacture molded parts tailored to unique operational needs ensuring reliability, durability, and cost-efficiency. Whether you’re innovating a new system or optimizing existing equipment, Arvico supports you from concept to prototype to production, all with quick lead times and uncompromising quality.

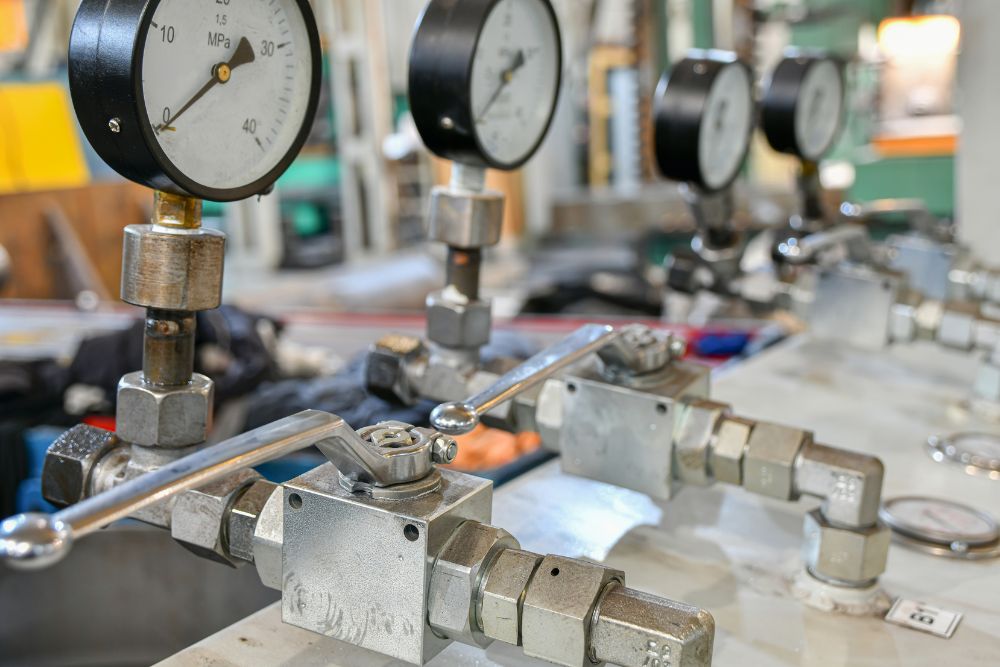

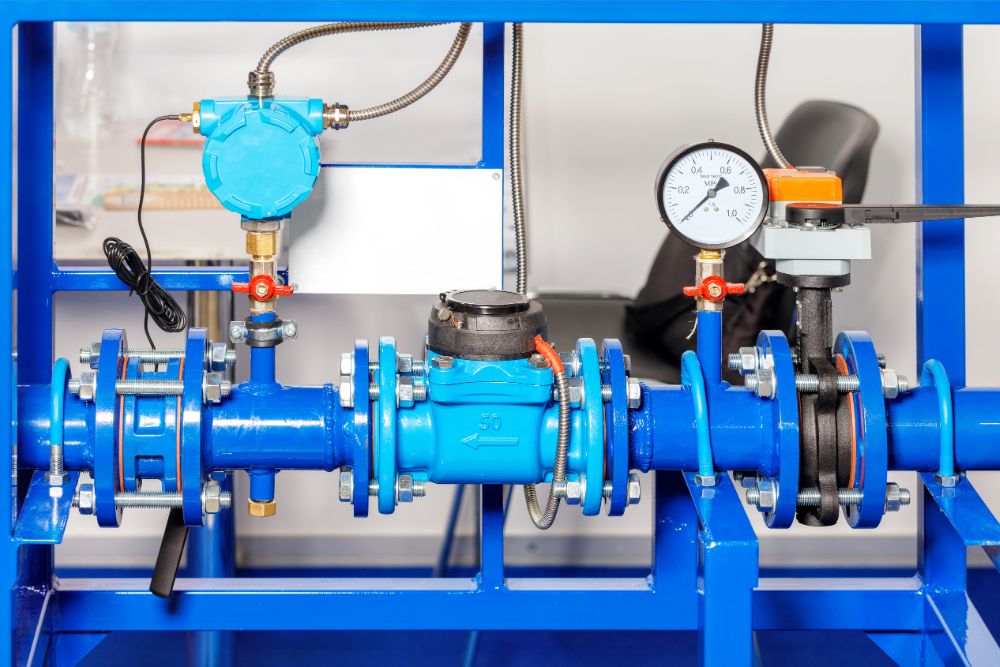

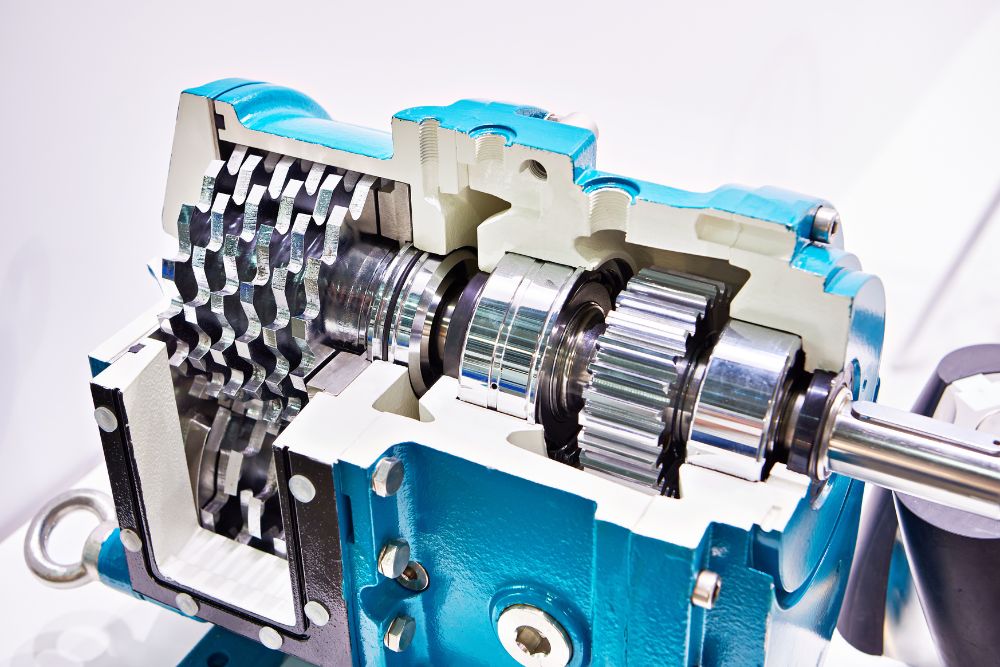

Pumps & Valves

Applications

Pharmaceutical & Biotechnology

Applications

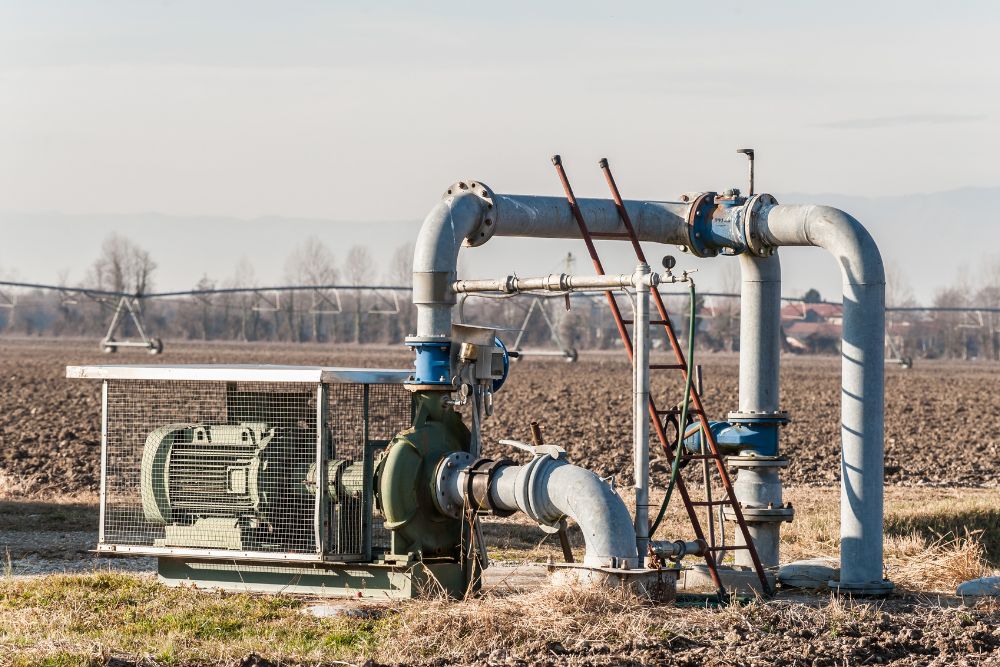

Petroleum & Oil Refining

Applications

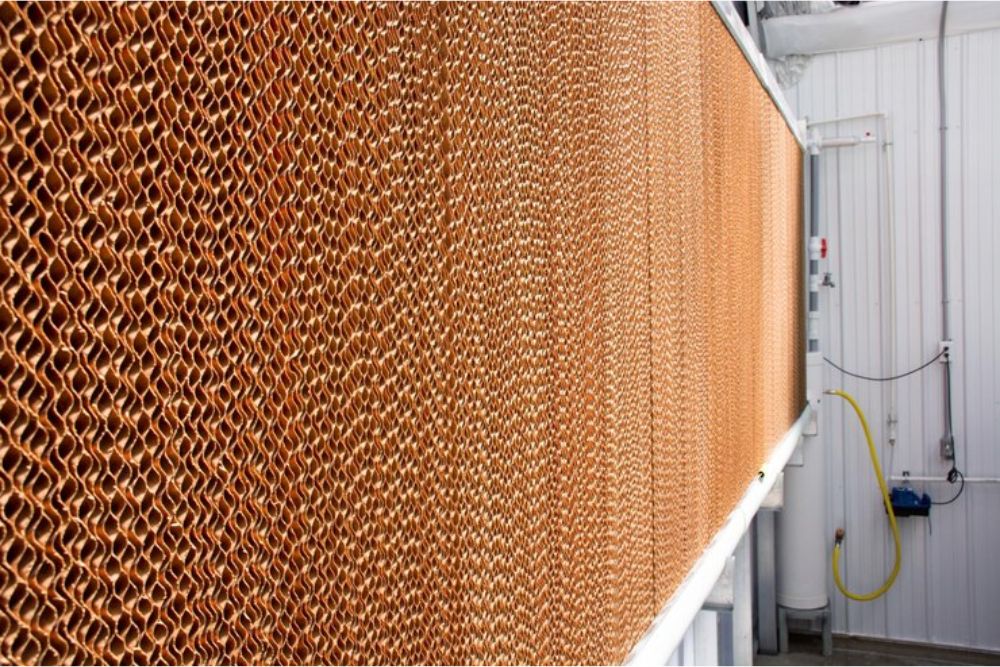

Food, Beverage & Dairy Processing

Applications

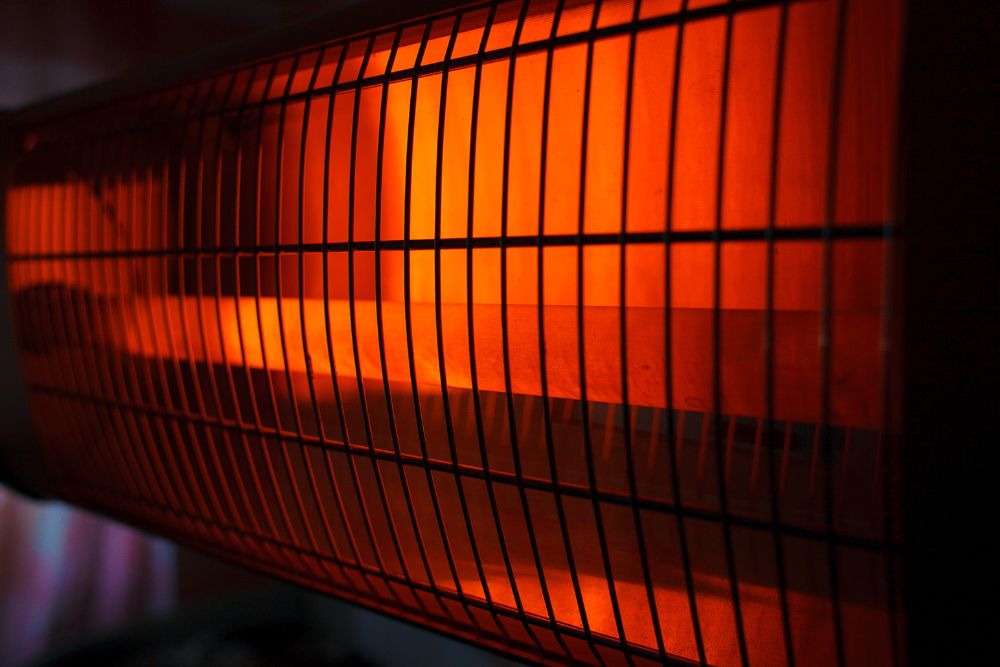

Nuclear & Power Generation

Applications

Pulp & Paper

Applications

Chemical & Gas

Applications

Sugar Industry

Applications