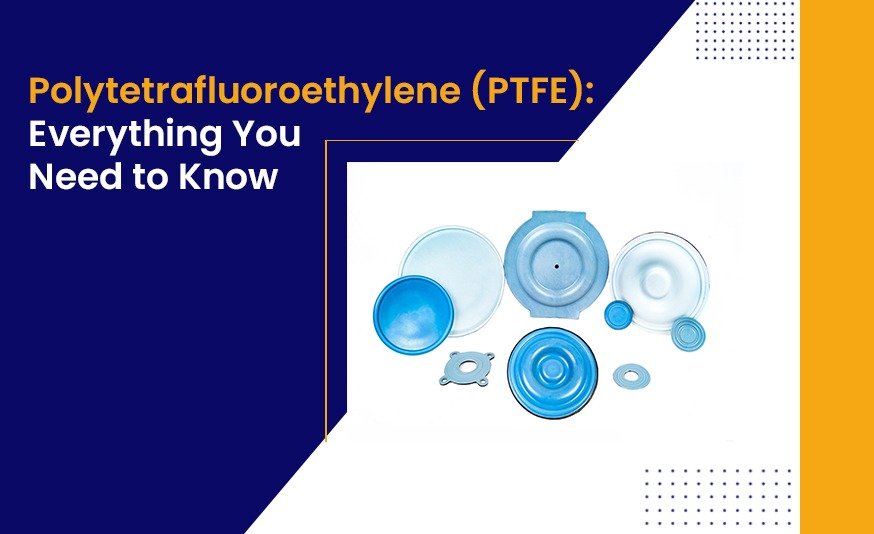

Polytetrafluoroethylene (PTFE Diaphragms): Everything You Need to Know

PTFE Diaphragms – Introduction

Arvico Rubber’s PTFE diaphragms are some of our portfolio’s most commonly ordered components, thanks to their exceptionally resistant properties and strength.

Did you know that PTFE was discovered accidentally? It was discovered in 1938 by an American chemist called Roy J. Plunkett. This chemist registered the material as Teflon and trademarked it in 1945.

Right now, PTFE is used to make all kinds of products starting from small kitchen appliances to surgical implants, firefighter equipment, and more. Lets read everything about Polytetrafluoroethylene .

What is Polytetrafluoroethylene?

Polytetrafluoroethylene (PTFE) is a type of plastic that is used in a variety of industrial and consumer applications. PTFE is commonly referred to by the brand names Teflon, Hostaflon, and Fluon. All these are trademarked names of PTFE.

This wonderful synthetic material has a non-stick surface that makes it a great choice to make rubber components from. It has multiple other beneficial features that we will cover in the coming sections. Technically, PTFE is a fluoropolymer of tetrafluoroethylene. Tetrafluoroethylene is a fluorocarbon.

Characteristics and Properties of PTFE Diaphragms

There are a lot of properties of PTFE that make it a favorite choice of material in most industrial settings.

Here are some of the notable properties of PTFE.

- PTFE is a solid at room temperatures and has a preferable melting point of 600 K.

- PTFE has a density of 2200 kg/m3.

- PTFE diaphragms and other PTFE components are FDA approved, making them a perfect choice for food and beverage industries and pharmaceutical units.

- PTFE is hydrophobic, which means water or water-based substances cannot wet the material.

- PTFE has one of the lowest coefficients of friction when compared to most other solids. The coefficient of friction of PTFE is measured to be about 0.05 to 0.10. This is the third-lowest value, only after aluminum magnesium boride (BAM) and diamond-like carbon. This is also the reason why PTFE diaphragms are one of the most preferred diaphragms in the industry.

- The melting point of PTFE is 326.85 °C.

- PTFE is very slippery, and that’s why the material is used as an outer coating to prevent insects from climbing up.

- PTFE is non-reactive to most chemicals. The only chemicals that can affect PTFE are highly reactive alkali metals and fluorinating agents like cobalt (III) and xenon difluoride.

- PTFE is non-toxic, odorless, and tasteless, and these are added advantages that make the material a preferred choice. Industries that produce edible products choose PTFE diaphragms, especially for these factors.

- PTFE is steam-proof too, and can hence be used in applications where high steam processes may damage the components. PTFE can also be sterilized.

Applications of Polytetrafluoroethylene (PTFE)

Here is a list of some of the common applications of PTFE and its products.

- Rubber components

When it comes to industrial-range PTFE rubber components, the below are options to choose from.

- O-rings

- PTFE diaphragms

- Valves

- Insulated transformers

- Wire insulators

- Surface coatings

- Bearings

- Insulators

It is said that 50% of all the PTFE materials produced are for insulation and wiring purposes. These are used in computer hardware applications and in aerospace industries.

- Composites

Composites are substances made using a combination of two or more materials. PTFE is combined with fiberglass or carbon fiber to make fiberglass composites and is used in aerospace industries. Using PTFE gives these composites a non-sticky nature, which is needed in specific cases.

- Kitchenware

One of the common uses of PTFE is in the kitchenware industry. There are a lot of utensils and cookware made from this material because of its non-sticky and hydrophobic properties.

How do Fillers and Additives Enhance PTFE Properties?

PTFE, by itself, is a very productive and robust material. However, when you use additional fillers and additives, the properties enhance even more, giving the users better benefits.

Let’s consider PTFE diaphragms, for example, here. These diaphragms have two properties that you can enhance by adding the right fillers/additives to them.

- Creep rate – Creep rate is the rate of deformation of a material when it is subjected to constant stress.

- Wear rate – Wear rate is the rate at which the material experiences wear and tear due to everyday use.

Now, for any diaphragm, the slower the creep and wear rate, the better it is for the product.

Many industries that produce PTFE diaphragms add fillers like bronze, steel, glass fiber, carbon fiber, graphite, and carbon to improve the product’s performance.

Depending on the fillers added, the hardness of the diaphragm can be improved, the wear rate can be bettered, the flexibility can be increased, and the ability to handle extreme temperatures can be enhanced.

Popular Techniques Used to Process PTFE Diaphragms

The properties of PTFE depend majorly on the production process. PTFE is a very tough material, and molding it into shapes of choice is usually difficult. The normal production methods don’t work effectively here.

If you want to use good quality and effective PTFE diaphragms, check the production process used in making PTFE.

Here are some of the popular techniques used.

- Sintering – This is the process of using hot stamping, compression molding, and pressing to force PTFE into required shapes.

- Paste Extrusion – In this technique, a chosen hydrocarbon is mixed with PTFE prior to molding, and the mix is quickly fabricated into the shapes and sizes required. Later on, the hydrocarbon is vaporized before the mold can be pressed, stamped, and permanently set.

Here is a sample process of producing PTFE in industries.

- Chloroform is first produced using methane, hydrogen chloride, and chlorine.

- Chloroform is then combined with anhydrous hydrogen fluoride.

- This produces chlorodifluoromethane. By heating this chemical in the absence of air, tetrafluoroethylene (TFE) is produced.

- TFE goes through polymerization to become PTFE.

Limitations of PTFE Diaphragms

- PTFE is not a cheap polymer. It falls under the slightly expensive category because of the difficulty in producing end components like PTFE diaphragms.

- Mass production of PTFE is also expensive and time-consuming.

- It is not easy to mold or weld PTFE into different shapes. The process is effortful.

- Joining multiple PTFE materials is quite challenging.

- If you use PTFE diaphragms in extremely toxic atmospheres, they may get eroded or damaged.

Conclusion

PTFE, when produced right, can be a very solid and trustworthy material to use in several industrial applications. By picking Arvico products like PTFE diaphragms, O-Rings, Valves, and other components for your production process, you can also improve the processes’ efficiency and safeguard expensive equipment.

When you choose PTFE, make sure you check the way it is produced and its physical properties. If there are fillers added, do look at the compositions even more carefully.

Arvico Rubber brings to you exceptional quality PTFE diaphragms and other components that are highly resistant to chemicals and temperature. Do get in touch with us to know more. We have the capacity to produce high-quality PTFE components in mass volumes and in the exact sizes you prefer.