In today’s demanding industrial landscape, Polytetrafluoroethylene (PTFE) has become a game-changer. Also called Teflon, PTFE is known for its exceptional chemical resistance, low friction, thermal stability, and non-stick properties. It is the go-to material for industries requiring precision, durability, and efficiency. At Arvico Rubber Industries, we specialize in high-performance PTFE components engineered to meet the strictest international standards, ensuring superior reliability in harsh operating conditions.

What Makes PTFE an Industrial Marvel?

PTFE’s unique properties set it apart from conventional materials:

- Unmatched Chemical Resistance– Withstands acids, bases, solvents, and aggressive fluids, making it ideal for extreme environments.

- High Thermal Stability– Performs flawlessly in temperatures ranging from -200°C to 260°C, with a melting point of 327°C.

- Ultra-Low Friction– Ensures smooth, wear-resistant operation, reducing energy losses in dynamic applications.

- Non-Stick Surface– Prevents material buildup, ensuring easy cleaning and maintenance.

- Superior Dielectric Strength– Ideal for electrical insulation in high-performance applications.

- Exceptional Durability – Long-lasting components that withstand mechanical stress, pressure, and thermal expansion.

Industries Leveraging Arvico’s PTFE Solutions

Our PTFE components are trusted by leading industries worldwide:

- Chemical Processing– Used in seals, gaskets, and liners for resistance against corrosive substances.

- Automotive & Aerospace– Ensures reliability in extreme temperatures and friction-intensive environments.

- Electrical & Electronics– Provides superior insulation in high-voltage and precision electronic applications.

- Food & Beverage– FDA-compliant, non-toxic PTFE is used in food processing equipment and conveyor systems.

- Medical & Pharmaceutical– Biocompatible PTFE is essential for surgical instruments, implants, and fluid transfer systems.

- Oil & Gas– Plays a crucial role in high-pressure sealing, pipeline protection, and valve applications.

Arvico’s Premium PTFE Components

Our state-of-the-art manufacturing ensures precision-engineered PTFE solutions tailored to your operational needs:

- PTFE O-rings– Exceptional sealing performance in extreme pressure and temperature conditions.

- PTFE Washers & Gaskets– Prevent leaks and enhance equipment lifespan in industrial applications.

- PTFE Bellows– Absorb thermal expansion, vibrations, and system misalignments in pipelines.

- PTFE Rods & Strips– Customizable raw materials for machining into precise industrial components.

- PTFE Chevron Sets & Gland Packings– High-pressure sealing solutions for hydraulic and pneumatic applications.

- PTFE Diaphragms– Flexible and chemical-resistant solutions for critical fluid control systems.

Why Choose Arvico for PTFE Solutions?

At Arvico Rubber Industries, we go beyond manufacturing-we deliver excellence through:

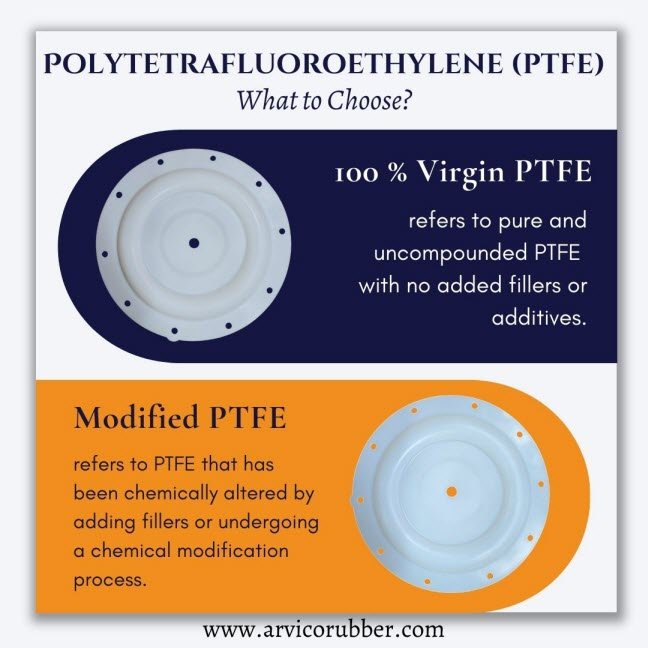

- Advanced Material Selection– We use high-quality PTFE grades (Virgin and Modified) that comply with ISO, FDA, and ASTM standards.

- Precision Engineering– Our CNC-controlled manufacturing ensures exacting tolerances for critical applications.

- Customization Expertise– We design tailor-made PTFE components based on industry-specific needs.

- Rigorous Quality Control– Each component undergoes stringent testing for durability, chemical resistance, and thermal stability.

- Global Compliance & Certifications– Our PTFE products meet international safety and performance benchmarks.

Ensuring Performance, Every Time!

PTFE components are the backbone of various industrial and commercial applications. Manufacturers, exporters, and wholesale suppliers prefer PTFE components for their unmatched reliability and durability. The material’s ability to withstand extreme conditions and its versatility make it a valuable addition to any industrial process. Whether it’s reducing downtime, enhancing operational efficiency, or ensuring safety, PTFE components deliver consistent results.