Introduction

Rubber is one of the most used raw materials across different industries. Both natural and synthetic rubber is used extensively to make everything starting from the tiniest of home goods to massive structures used in industries. There are different types of rubber molding used in producing rubber components, and the features of the product would depend on the manufacturing process and the type of molding chosen.

Did you know that India is the fourth largest consumer of rubber? According to sources, the per capita consumption of rubber is 1.2 kg. The Indian Rubber Industry states that rubber manufacturing companies in the country produce more than 35,000 different rubber products. All these products use one of the below molding types to be manufactured.

Here are the three most popular types of rubber molding used by industries to create rubber components and products.

Rubber Injection Molding

Rubber injection molding is probably the most straightforward and commonly used type of rubber molding chosen by manufacturers across the world. As the name specifies, this type involves injecting a rubber compound into a mold and keeping the mold under high pressure for the component to get shape.

There are four sub-components of rubber injection molding.

1. Organic rubber injection

Organic rubber injection starts with prepping the rubber component by stripping and mixing it before feeding it into the screw. As a result, there is no need to preheat the rubber and the completion type reduces too.

2. LSR injection

Liquid Silicone Rubber (LSR) injection is a type of liquid injection method used specifically for silicone rubber. Parts of liquid silicone are sent into the injection unit. This is cured and injected into the mold.

3. Thermoplastic rubber injection

Thermoplastic rubber injection is a process of using thermoplastic elastomers, also known as TPEs, to create molded components in. This type of rubber molding process needs high temperatures to work and that is one challenge in using TPEs. However, with TPEs, the manufacturer can avoid the initial tasks of mixing and vulcanizing.

4. Custom rubber injection molding

This is a completely customized process where the manufacturer decides every single aspect of injection molding, starting from the raw material used, the injection molding process, and the temperature and pressure decided based on customer requirements.

Advantages of rubber injection molding

- Lower costs – injection molding is usually cheaper to achieve, and that makes it a preferred type of rubber molding.

- Easier process – rubber injection molding is a straightforward process that does not involve many complicated steps, and this is also an advantage of using this over other types of rubber molding.

- Better precision – in case smaller and more intricate parts are to be produced, the best choice in the list of different types of rubber molding is rubber injection.

Disadvantages of rubber injection molding

- Higher setup costs – while the cost of producing rubber components is lower for rubber injection molding when it comes to the setup costs, this involves more initial expenses. The cost of the production machinery is higher too.

- Generation of waste – the process of producing rubber using this type of rubber molding generates more amounts of waste that can be avoided when other types of molding processes are used.

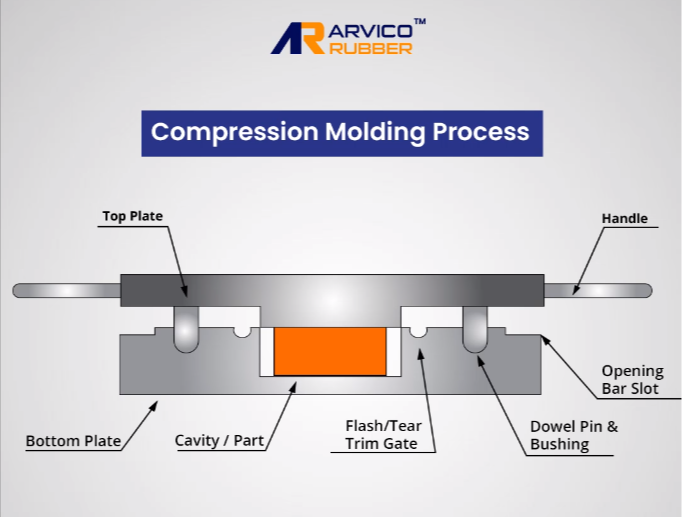

1. Compression Molding

Compressing molding is also one of the popular types of rubber molding used in creating rubber components across different industries. As the name suggests, this process uses compression to create the structures.

Preheated materials are poured into the mold or cavity, and the mold is then closed and compressed at a certain temperature and pressure. Usually, hydraulic pressure is used to achieve the effect.

The compression is applied for a specified period of time, and then the formed structure is removed.

A compression unit usually consists of the following parts.

- A movable top half of the mold

- A fixed bottom half of the mold

- An ejector pin to remove the finished product

Advantages of compression molding

- Low initial setup cost – the initial cost of setting up is quite low, compared to other types of rubber molding.

- Works for low-volume production – the cost of production does not increase, even for low-volume outputs.

- Works best for large components – large components can be easily produced using this method.

Disadvantages of compression molding

- Low dimensional tolerance – this type of rubber molding does not work well for components that are small and intricate. Precision molding may be needed for certain components where even the smallest of shape changes may be detrimental. In that case, compression molding cannot be chosen.

- High wastage production – there is high wastage produced with the production process.

- High production time – the time taken to produce components is high, as there is a considerable waiting time after compression.

2. Transfer Molding

Transfer molding is another of the popular types of rubber molding that produces rubber components of different types. There are two major halves of the mold. The upper half has a cavity where the raw material needs to be placed.

The upper half comes with a plunger that can be used to push the raw material through a narrow cavity.

The raw material goes to the heated mold through this cavity and takes shape. Once the product cools down and is vulcanized, it can be extracted through the bottom half by removing the ejector pins.

Advantages of transfer molding

- High dimensional tolerance – as long as the mold is shaped right, the final product can be designed to have high dimensional tolerance.

- Metal-rubber bonding – this technique can be used to create precise and high-quality metal rubber bonding designs.

- Easy molding process – the overall process of molding is straightforward and easy, saving time and effort.

Disadvantages of transfer molding

- High initial costs – the initial setup costs for this type of rubber molding are pretty high.

- Additional finishing processes – the final product must go through additional deflashing techniques to be completed.

- Additional prepping time – the raw material needs to be cured for a specific amount of time before it can be molded. This increases the overall cycle time of production.

3. Rubber Molding with Arvico Rubber

Arvico Rubber is your favorite rubber component manufacturer, and we specialize in using all these three types of rubber molding to create components based on your specifications.

Arvico Rubber comes with 55+ years of experience in this industry, and some of the components we specialize in are gaskets, diaphragms, seals and sleeves, expansion joints, O-Rings, and bearing bushes.

We understand how important dimensional tolerance and quality are to our clients, and that is why we always have prep meetings to understand the requirements completely before accepting projects.

Our design team can produce molds with 100% precision, and all finished products go through multiple levels of quality testing before reaching our clients.

Whatever type of rubber molding you want for your components, we get that done in the quickest possible time. Please get in touch with our expert consulting team to know how we can help improve the quality of your manufacturing process with our components.